Swedish startup folds e-motorcycles using sustainable materials

- STILRIDE aims to produce sustainable e-motorcycles and e-scooters using a groundbreaking process dubbed industrial origami

- The company has raised 2.5 million pounds to bring the startup’s first product to the mass market, the Sport Utility Scooter One (SUS1)

- In the US, e-bikes import outpaced electric cars in 2021

E-bikes, which include e-motorcycles, e-scooters and e-bicycles, are becoming highly sought after as consumers look towards more sustainable modes of transport. In the US, the Light Electric Vehicle Association reported that import data showed e-bikes outpaced electric cars in 2021. Nearly 790,000 electric two-wheelers were imported into the US in 2021.

According to a Bloomberg report, nearly all e-bikes sold in the U.S. are imported and most retailers are selling inventory as fast as they can restock it, with the import number acting as a good stand-in for sales. However, the US still lags far behind Europe and Asia, where annual e-bike sales are about 3 million and 35 million respectively.

In Europe, Germany, the Netherlands, and France dominate the European market. Mordor Intelligence reports the European e-bike market to be valued at USD 8.01 billion in 2020, and it is expected to reach US$16.58 billion by 2026.

Part of the increased demand for e-motorbikes and e-bicycles is due to the COVID-19 pandemic. Consumers are moving from public transport towards personal vehicles, with e-bikes being the most economical option, especially for those living in Europe’s bustling cities.

Regulations for e-bikes in Europe have also been changing as two-wheeler adoption increases. For example, the French government has created a new vehicle category in its traffic code for so-called cyclomobiles légers, light mopeds. This initiative seems to be aimed at accommodating e-scooters with a saddle and e-bikes without pedals.

With huge opportunities in Europe and the US, Swedish technology and design startup STILRIDE aims to produce sustainable e-motorbikes and e-scooters using a groundbreaking process dubbed ‘industrial origami’.

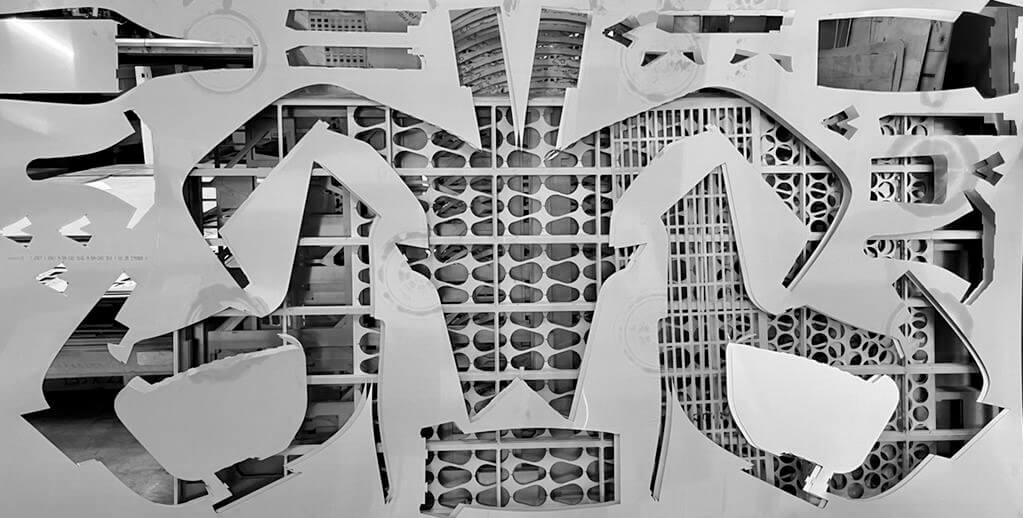

Industrial origami is a technique that involves robots that can fold single sheets of recyclable steel into intricate, lightweight, and durable new structures – significantly reducing the environmental impact of production. This process is being used to create the chassis and body for a fleet of next-generation e-motorcycles which will be made available to consumers in Europe later this year.

Industrial origami is a technique that involves robots that can fold single sheets of recyclable steel into intricate, lightweight, and durable new structures. (Source: STILRIDE)

Sustainable, foldable manufacture of e-motorcycles

STILRIDE’s pioneering industrial origami technology, called STILFOLD, is the brainchild of best friends Tue Beijer and Jonas Nyvang, who possess backgrounds span the worlds of fashion, industrial design, and engineering. With STILRIDE, the duo aims to reimagine how high-performance electric-mobility products are manufactured and distributed — using cutting-edge steelwork, advanced robotics, and ambitious design.

The company has also just raised 2.5 million pounds to enable the manufacturing. The injection of funding will be used to bring the startup’s first product to the mass market, which is the futuristic Sport Utility Scooter One (SUS1).

Unlike traditional scooters (which consist of a tubular frame and plastic body), the SUS1 is constructed by folding sheets of stainless steel over curves, much like origami. Not only does this result in a durable body and distinctive aesthetic, but it also requires fewer raw materials and reduces labor costs. Compared to a traditional scooter, the SUS1 requires 70% fewer components, driving a 25% reduction in labor costs and a 20% reduction in material costs.

“The STILFOLD technology is best described as a dance between robots and steel. We have created a process that builds high-performance, sustainable personal mobility products that are also durable, lightweight, and desirable. The SUS1 is the first application of the technology and the ambition is to apply it to cargo bikes and trailer products,” said Nyvang, the co-founder and CEO of STILRIDE.

(Source: STILRIDE)

E-motorcycles are the first application of STILRIDE’s proprietary STILFOLD technology. Next, STILRIDE will use this technique to add cargo bikes and trailers to its product offering.

To reduce the product’s carbon footprint, the company is aiming to create a production process that allows the steel sheets to be flat-packed and shipped to local factories across Europe, where they’ll be folded and fitted with a hub motor and battery pack. Already, the climate impact of developing the SUS1’s chassis is half that of traditional scooters.

Nvyang explained that STILFOLD enables manufacturers to minimize resource consumption and waste, cut down on labor costs and ultimately reduce the environmental impact of production. They plan to launch in Europe first as it’s a market that relies heavily on outsourcing and has much to gain from increasing its domestic manufacturing capabilities. STILRIDE also has plans to expand into other international markets.

There are already 90,000 people on the waiting list for the STILRIDE SUS1 e-scooter, with the first pre-series of e-motorbikes set to be released to customers in the autumn of 2022.