Are industrial robots safe alongside humans?

- An independent report has found that Amazon warehouses with robots present correspond to higher injury rates among employees

- The report casts doubt over the industrial application of robots, which has been steadily booming and catalyzed by Covid-19

- Workplace safety — especially in the presence of robots — continues to be a real, complex, and ongoing issue for all businesses

The Center for Investigative Reporting has acquired internal records for 150 of Amazon’s warehouses or ‘fulfillment centers’ over the last four years, and has found that sites with robots correlate to 50% higher rates of serious injury.

The reporting firm accuses the retailer of “bald misrepresentations”, and an intention to “hide its growing safety crisis” from the public and lawmakers alike. In response, Amazon said its numbers were high because it encouraged the reporting of even minor incidents (that’s an argument somewhat akin to Trump’s ‘we do more tests so there are more cases’, ‘tis is not).

Whether purposely misleading the masses or seeing safety numbers that inevitably result from their ever-increasing scale, Amazon continue to emphasize their “deep focus on the safety of teams”.

Robots show no sign of retreat

Amazon initially introduced robots into its warehouses after acquiring a robotics manufacturer in 2012. This year, the pandemic has given rise to a new boost in use for industrial robotics.

According to some forecasts, we could see the deployment of four million commercial robots across 50,000 warehouses in the next five years. With robotics-as-a-service emerging as a more commercially viable option, the lens has fallen both on their efficiency (as a route to longer uptimes) and the impact on the human workforce. Pickers at one Amazon warehouse, for example, said they had seen their expected number of items to handle grow from 100 to 400 an hour (to match the robot’s capabilities), or had been re-routed to workstations, stagnancy or monotonous tasks.

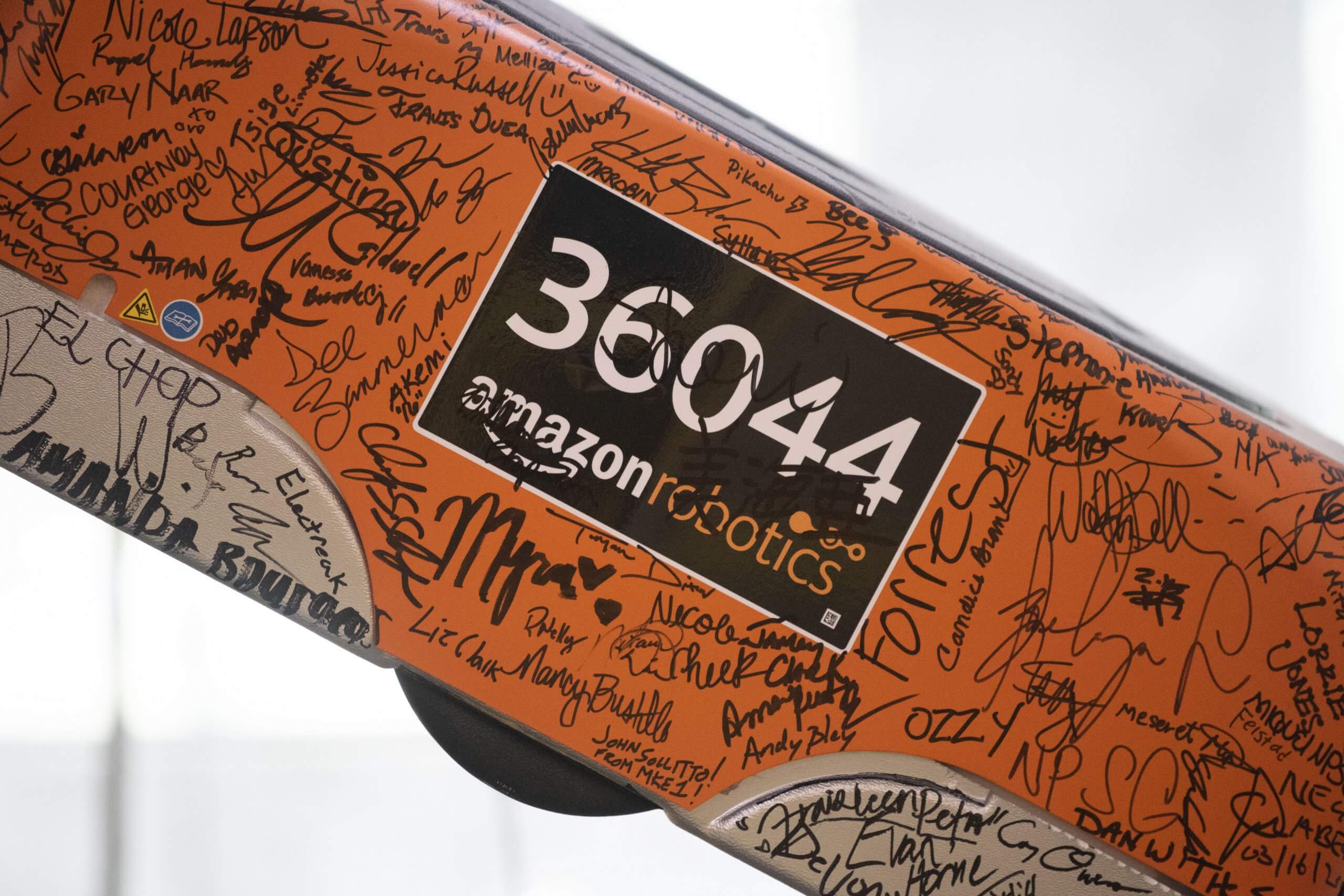

Amazon Robotics works, signed by the entire staff on the opening day of the Kent, Washington Fulfillment Center in March of 2016. Source: AFP

The argument is nothing short of polarising. Some publications have professed that robotics is minimizing lifting injuries, falls from height, and managing worker fatigue with its tireless robotic arms. This industrial emphasis is accompanied by slightly more left-field applications, with robotic assessment of burning buildings (thus keeping fighters out of the firing line) to nuclear clean-ups and fuel-tank inspections. With the bulk of their use conducive with heightened efficiency and safer spaces, the spotlight is apt to fall – as it does in this case – on where humans and robots are intersecting problematically.

Does this Amazon-focused report, however, cast a shadow over industries’ increasing onus on robotic deployment, and is the concern fair?

Amazon’s warehouse woes?

So, The Center reports that last year alone, there were 14,000 “serious” injuries in Amazon workplaces. Such injuries require days off or job restrictions. Their overall injury rate was almost double the industry standard, and the report posits that it was pushed to such a troubling point by warehouses with robots in.

A few warehouses reported as many as five times as many injuries as the industry average, measured in serious injuries per 100 workers.

Amazon’s chief executive Jeff Wilke is pretty adamant of the robotics’ safety, though claiming the technology is not only “making jobs safer”, but also “making jobs more interesting, allowing people to take advantage of their innate human creativity”. Though a familiar and somewhat credible argument (and beyond the role of robots in industry), the aforementioned concerns of employees mean Wilke’s words must be taken with a pinch of salt.

YOU MIGHT LIKE

No, robots didn’t secretly kill 29 scientists in a lab

Cases for the defense:

Reveal’s analysis of the data it received found that 2019’s “Prime Day” sales period was “the year’s most dangerous week for injuries at Amazon fulfillment centers, with nearly 400 serious injuries recorded across the country”. If peak periods give rise to chaos in the warehouses, then the relative benefits of robots are somewhat nullified, no? Perhaps not. Peak periods mean more staff, and so an inevitable increase in injury numbers, though no tangible increase in rates (injury per X number of workers).

Workplace safety is a real, complex and ongoing concern for every business (even more so now with Covid-safe environments required for operations to continue). In the past, there have been plenty of disputes of the “robots are taking over” ilk, but this is scarce the case. The industrial co-existence of robots and workers is in its infancy, and though there’s no uniform solution, one can’t help but feel it lies at the crossroads of increased efficiency, employee empowerment, and, most pivotally, stringent safety measures.