How a data-sharing startup could help supply chain recovery

- COVID-19 supply chain disruption has been compared to WWII

- A supply chain data startup is making its vast database available to provide a ‘birds-eye-view’ of supply chain disruption

- It serves as an example for how data-sharing can help industries recover

The recent disintegration of global supply chains has happened at an unprecedented pace, and it’s left the logistical links between manufacturers, transportation, and suppliers ruptured.

With little else to compare the scale of disruption to in recent history, commentators’ nearest go-to is that of World War 2, which similarly left supply chains in pieces around the world (although the term supply chain wasn’t coined until the 80s).

Back then, of course, supply chains – though equally as sophisticated – were rudimental in terms of technology.

Today, our reliance on supply chains has led them to become a focal point for advanced technology – dockets and ledgers have been replaced by AI, IoT and advanced analytics – all of which amasses huge volumes of data for the companies deploying them, providing insights to guide optimization.

Much like every other industry or sector, data is now the lifeblood of the supply chain, and it may well be the key to ensuring its damage in a crisis can be limited, and its recovery expedited.

Big data to the rescue

Even though the easing of lockdowns and discussions of exit strategies in some countries and regions are a glimmer of hope for manufacturers and suppliers in the recovery of supply chains, getting back on course will be a Herculean challenge.

A lack of coordination in the reopening of large economies, like news of Germany restarting some activities while others remain firmly shut, could lead to staggered recoveries across markets, and supply chains may take years to reestablish the fluidity they once had. With companies being left in the dark regarding the state of the manufacturers and supply – having a clear picture on the state of transportation hubs and operations has become the weakest link.

As reported by TechCrunch, a Canadian startup Assent Compliance – that helps companies like GE and Rolls Royce manage complex supply chains – is offering a free data tool, allowing companies to upload their bills of materials, and to see which segments of their existing supply chains have been disrupted along the way.

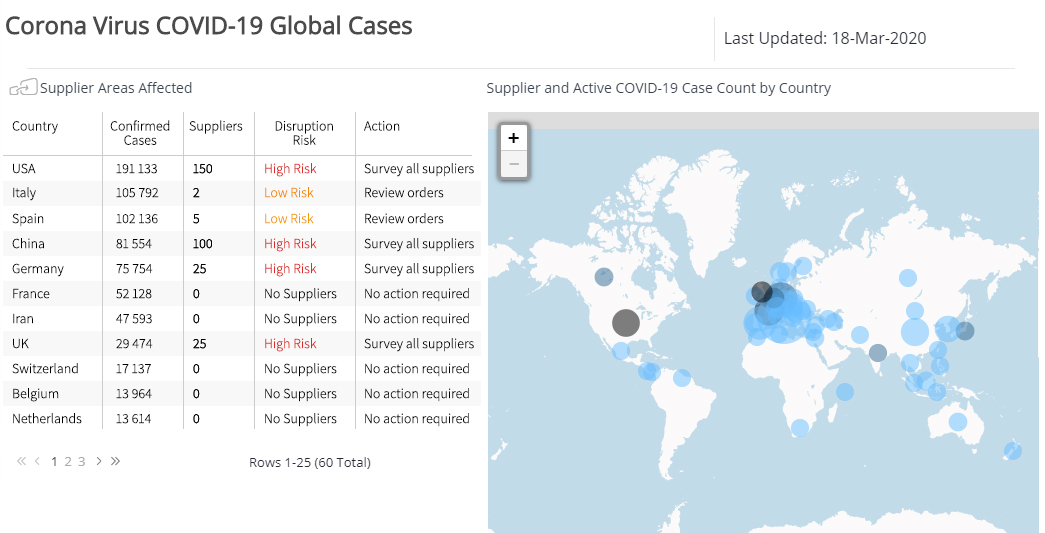

Organizations – those separate links in the supply chain – can now leverage a database of 1,000 customers and 500,000 suppliers listed on Assent’s platform, and cross-reference it with their own data, in order to gain a bird’s-eye view of supply chain links to maneuver through the disruption.

Company co-founder Matt Whitteker explained this is possible through the combination of massive data sets from various sources. “We have all that data on hand — we have location data for suppliers. So it’s just a matter of applying that with third-party data sources […],” he told TechCrunch.

“[…] companies upload their bill of materials that basically outlines all their parts, components and commodities, and who they get them from, which basically represents their supply chain,” Whitteker said.

Source: Assent Compliance

Other third-party data includes information available from organizations like the World Health Organization or Center for Disease Control which when overlaid can help companies track and monitor the health and operability of certain transport routes.

Essentially, the enhanced transparency could be the support needed for companies to adapt and restrategize their road maps for shipping, allowing them to carry on despite the ongoing breaks along the global supply chain.

The move by Assent Compliance is just one example of how data-sharing can work to the benefit of entire industries, particularly in times of crisis where every member is affected to a degree, and market success requires collective recovery.