Progress on the path to full warehouse automation

Amazon recently announced aims to make its warehouses fully automated in the next decade.

It’s a tantalizing prospect for the e-commerce-cum-logistics giant— cutting out human labor costs, driving efficiency and opening new ideas for simplicity in inventory management.

Alibaba’s warehouses are following suit in Asia. As of last year, the firm opened a 700-robot warehouse outside Shanghai, manned by just a handful of humans to pack items and supervise the robots. The technology helped the Asian e-commerce heavyweight deliver a record US$30.7 billion sales.

Despite these businesses moving with the technological pace that might make it possible, the thought of robots completely taking over a working environment is still some way off at present— the robots cannot yet imitate human capabilities.

What can’t they do?

Earlier this year, Scott Anderson, director of Amazon Robotics Fulfilment noted that AI technology in its current form has limited applications in warehouse environments. The robots still do not have the cognitive abilities that humans do, he said, making it impossible to perform every task without human supervision.

This puts certain tasks— which are simple for humans— well out of reach of the technology’s current capabilities. For example, Amazon hasn’t yet deployed robots to pack orders for its Grocery Store; machinery can’t choose fresh fruit— it requires eyesight, sense of touch and sense of smell to pick food that’s fresh.

Robots need humans

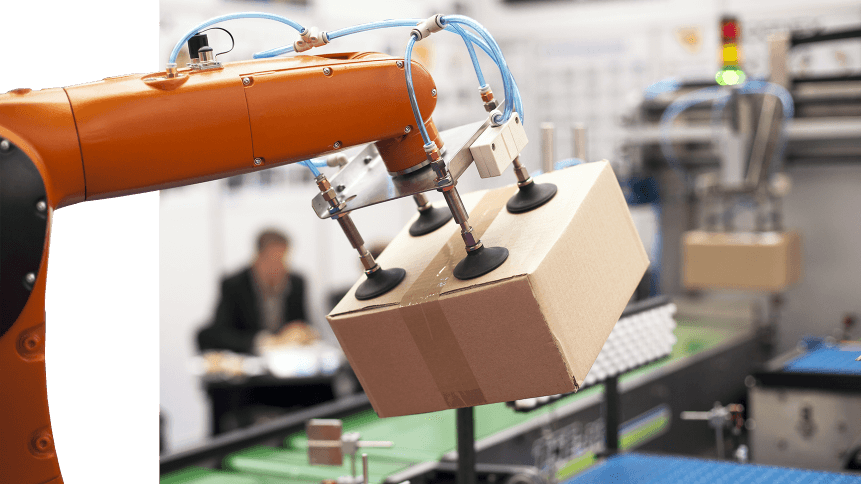

It is, however, just a matter of time before these capabilities are developed and learned, as the robotics market continues to accelerate. In research conducted by ABI, the firm estimated that 4 million commercial robots will be deployed across 50,000 warehouses by 2025.

This massive growth in autonomous machinery is driven largely by forecasted demands in e-commerce, and the ability to handle orders at scale, round the clock.

But while robots and automated machinery will be built and programmed to handle specific tasks— and warehouse automation and AI software will begin to orchestrate supply-chain operations— humans will still be required to design, train, monitor, and dispose of the technology.

Even in some of the most advanced cases, systems rely on machine-human cooperation. UK online grocery retailer Ocado’s ‘robotic grid’ (see video below), consists of 1,100 robots working in unison. They pick up and reorder crates from each stack and deliver them to pick stations where personal shoppers assemble the customer orders.

While warehouse robotics are bringing massive benefits to efficiency, human senses cannot yet be relieved from the warehouse floor.

Are we ready yet?

From a technological sense, it may seem counterintuitive that AI-driven machinery requires human oversight, but that may be a component we shouldn’t take for granted. As reported by the Verge, Amazon recently put in place a staff management system that tracked and rated staffs’ productivity.

The system had the freedom to raise flags and even terminate employees that it deemed “not productive” without human oversight, drawing fire from human rights groups across the US.

The current limitations when it comes to warehouse automation and AI may be welcome before we can appreciate just how much leash we should give the technology. Most of us would rather be in charge of the machines, than the machines in charge of us.